NRRA Newsletter: May 2017

2017 Pavement Conference & Workshop

The planning for the 2017 NRRA Pavement Conference & Workshop is getting more intense as we approach the date (May 23rd & 24th). We are excited to have the opportunity to see so many of you, industry leaders and our alliance partners.

The highlights of the Conference/Workshop are:

Keynote Speech by Matt Witczak

Matt Witczak wrote Principles of Pavement Design, the bible for the pavement industry. He helped develop the mechanistic empirical design for asphalt that we are currently working to implement nationally. Matt also helped write some of the early design standards and worked with Superpave development in the early 90s. He is delivering the Gene Skok Distinguished Speaker Address.

Keynote Speech by Julie Vandanbossche

Julie Vandanbossche is a nationally respected concrete researcher. She has worked with whitetopping designs and helped develop whitetopping national standards. Julie has worked at Braun Intertec, the University of Minnesota and is currently a professor with the University of Pittsburgh. She will deliver the Gerry Rohrbach Distinguished Speaker Address.

"My presentation at the conference will serve as a great remembrance of our (mine and MnDOT's) effort to advance pavement research implementation findings to the Minnesota travelling public and remind everyone the strong role that MnDOT has played in improving pavement life and performance in the U.S. It will also be a great homecoming for me to see everyone at MnDOT again, after all of these years." --Matt Witczak

8 Case Studies

The eight case studies in the afternoon of May 24 come from our alliance members from all over the country. The subjects will include geotechnical testing, Finnish pavement management, joint sealants, asphalt recycling, and infrastructure as it’s affected by renewable energy. We asked our presenters to focus heavily on implementation, and we know they will deliver.

Expo and Posters

During breaks at the conference, various NRRA associate members will be available to talk about what they do, how they do it, and what happens to all of this research out in the field. Some of our academic members will also have posters to talk about their research projects.

Preconference Workshop

The preconference workshop will provide an opportunity to hear updates from the five NRRA work groups (Flexible, Rigid, Preventive Maintenance, Geotechnical, and Technical Transfer). There will be four workshops focusing on:

- Intelligent Compaction HMA

- SFDR, CIR, HIR Impact of Life Cycle Cost Analysis of Pavement Design/Performance

- Unbonded Concrete Overlays

- Advanced Performance Monitoring of Surface Condition

Picnic at MnROAD

The workshops on May 23 will be capped off with a tour and BBQ picnic at the world-famous research facility, MnROAD. Come visit with our research experts and take a look at our various test cells and research equipment.

You still have time if you haven’t already registered. Please share this information with your peers and others in the transportation and pavement industry. We look forward to seeing you in less than a month!!

Disk-Shaped Compact Tension Test: 4 Pilot Projects to be constructed in Summer of 2017

Predicting the future is, at best, a tricky business. Predicting the future of pavement is even more difficult because the timelines are so long.

Enter Disk-shaped Compact Tension testing (DCT), a performance test that gives pavement engineers a more complete picture of predicting how a stretch of road will survive over time under harsh cold weather conditions.

The key to improving the long-term performance of a flexible pavement is by minimizing the potential for low temperature or thermal cracking. Once a pavement cracks, all kinds of weather can compromise the road. “Water is our enemy,” said John Garrity, Bituminous Engineer for MnDOT. Cracks that allow water to seep in can eventually lead to roadbed deterioration and potholes.

The DCT test is essentially a way to determine the thermal fracture resistance of the mixture. It starts with a core and laboratory testing.

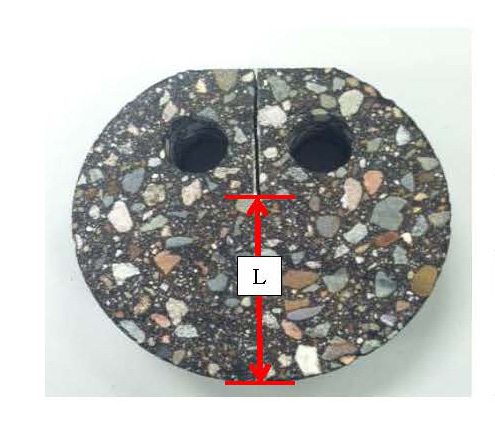

The core is trimmed, two holes are drilled, and a saw cut is made half way through the core.

The core is then placed in a special testing device that applies tension to the sample and literally pulls it apart until a crack appears. The fracture energy is then calculated – the higher the fracture energy, generally, the better the pavement will perform over time (or the less potential for thermal cracks to develop in the pavement). The minimum fracture energy for lower traffic volume mixes is 400 joules/m2 and 450 joules/m2 for higher traffic volume mixes.

One of the advantages of DCT, explained Garrity, is that rather than evaluating the individual components of the asphalt mixture, DCT evaluates how the mixture or final product will perform as a whole. It gives pavement engineers the whole picture, and when you are making predictions about the future of a pavement mixture, having the whole picture is vital.

Up until now, we have been developing the specification and test procedure, and we have also built a database of fracture energies from mixes around the state. This summer, we are taking it into the field on four pilot projects.

Two of the pilots will be on low-volume roads and two will be on high-volume roads—two in the metro Twin Cities area and two in more rural areas. Garrity said the DCT provision is restricted to new construction and reconstruction projects. One of the rural projects, I-35 near Duluth, involves a full-depth reclamation, so it’s essentially a new road and is a perfect candidate for DCT evaluation.

As much as the DCT testing is about predicting the future, it will also dictate how these four road projects proceed. If a pavement mix does not pass the test, failing to meet minimum fracture energy targets, it will not go down on the roadway.

Welcome New NRRA Associate Member

Help us welcome a new Associate Member First State Tire Recycling. It's representatives will be on the Tech Transfer Team and the Geotechnical Team.

Research Pays Off Upcoming Topics

This ongoing series of webinars happens every third Tuesday of the month at 10 a.m. (CST).

The next presentation will be on May 16 and will address the MnROAD/NCAT Pavement Preservation Study. The presenter will be Ramon Bonaquist, Chief Operating Officer of Advanced Asphalt Technologies.

Member Profile: WSB University

When we talk about the different layers that make up a road or pavement, there’s one layer that we often forget to mention: the layer of professional expertise and training that make it all possible. It’s invisible, but the road wouldn’t exist if it wasn’t there.

That’s what WSB University is all about. The construction firm, WSB and Associates, began an increased commitment to training back in 2006, and WSB University came into being.

Alex Young is the Education Coordinator for WSB, and she says that it’s about creating a space for learning to occur. As the organization ramped up its courses and offerings, it began expanding its audience by inviting clients, customers and associations to come in for training.

This was the brainchild of WSB’s CEO Bret Weiss, who saw this as an opportunity to give back to the construction industry that has supported his organization for so many years.

WSB University, to date, has hosted 60 different industry groups. It offers public classes that can count toward project management certification as well as leadership training.

The point of WSB University is to create not just a place where traditional classes can occur, but also building a space where collaboration is facilitated, says Young. That space for collaboration, where ideas are shared, is important to the work, we as an industry, do.

NRRA Exclusive: Technology Transfer Showcase and Training Workshop: May 18, 2017

MnROAD Facility (& webinar)

In the past two years, MnDOT has successfully implemented the use of digital image correlation equipment for multiple applications associated with pavement research. The non-contact measurement capabilities of the equipment also lend its use to other highway structures that experience small and rapid dynamic movements (bridges, signs, towers). This event will showcase the equipment, describe several case histories of its worldwide application, as well as provide specialized training for use on other highway structures.

RSVP for the workshop or webinar

This workshop/webinar is exclusive to NRRA Members and MnDOT employees.

NRRA Member Profile: Minnesota Local Road Research Board (LRRB)

Before there was a MnDOT and before there was a MnROAD and long before there was the National Road Research Alliance, there was the Local Road Research Board. It celebrated 55 years of existence a few years ago, and it has been a leader in ground-breaking (pun intended) road research for more than five decades.

It’s also sort of a rare bird. Only a few states having anything like it. The LRRB is so far ahead of the pack that it has become a model for other similar organizations. It works with MnDOT and universities to sponsor and fund road research that is particular to the needs of counties and cities.

On the pavement side, LRRB just completed a study (not out yet) looking at full-depth reclamation for urban and suburban streets. It also sponsored a presentation on the impact of lower temperature asphalt binder for coarse HMA mixes. In the upcoming year, it will be funding the second phase of a study on Prevention of Stripping Under Chipseals.

Kaye Bieniek, County Engineer for Olmstead County, says the organization is also working on a mix matrix that will translate research into usable information at paving sites.

The efforts of the LRRB, in many respects, parallel what the NRRA is trying to do. It encourages collaboration between contractors and city/county engineers and researchers. When it gets successful results in a research project, the study then goes to an implementation team. This team then decides how best to get the information out in the field. Sometimes that’s a spec, sometimes it’s a YouTube video.

Bieniek says that’s one of the LRRB’s biggest challenges: getting the information about research out to the people that need it.

With so many decades of experience to draw on, the NRRA can learn a lot from the LRRB. It’s great to have them as a partner as we expand our membership nationwide.

Follow NRRA on Facebook and Twitter

This newsletter is one way to connect and collaborate with the NRRA, and we are adding more. During TRB in January we launched our Twitter feed. Now we have established a Facebook page. This will give you a more immediate connection to trends in the industry, new research and our work as we build this alliance. Please follow us and encourage your colleagues to follow us. Thanks.