NRRA Newsletter: April 2018

2018 NRRA Pavement Workshop

We are a little less than a month away from our Pavement Workshop (May 23-24), and we hope you can register right away.

Last year at this time we had about 25 Associate Members of the NRRA. Now we have 45 associates. Please join us and them to talk about the future of our roads in May.

MIT Scan T2: Nothing else like it

We use a lot of devices to measure pavement in our industry—everything from bits of string to van-mounted ground penetrating radar arrays. Nevertheless, it’s rare to find a tool that has so many advantages, so many uses and so few drawbacks.

The MIT Scan T2* is designed to measure pavement thickness. It’s simple but also unique. It works by setting down circular metal plates before a pavement is laid down. Then you hover the MIT Scan T2 over the spot and it tells you how thick the pavement is. It uses magnetic pulses to do the measuring.

Here is a list of the advantages of this tool:

No cores: The main reason to use this tool is to avoid doing cores for thickness. We cut cores for density and in some cases we cut cores to determine pavement thickness. Cores are labor intensive and destructive to the pavement. Because the MIT Scan T2 is so accurate and has proven itself to be reliable, thickness cores can be avoided all together. In fact, near Morris, Minnesota, they are using this tool exclusively to measure pavement thickness according to Greg Johnson, assistant bituminous engineer for MnDOT, and no longer do cores for thickness.

Uniquely Versatile: Few measurement tools work for both asphalt and concrete, but this does both. Says Johnson, “this is really the only one that crosses over the border.” When measuring concrete thickness, you need to throw down steel plates. When measuring asphalt, you use aluminum plates and adjust the scanner respectively. Aluminum plates don’t work in concrete because there is already aluminum in the mix. The only other tool that works for asphalt and concrete is the device for measuring smoothness.

Accurate: According to Rob Golish, assistant concrete engineer with MnDOT, these devices are accurate to one or two hundredths of an inch. Accurate thickness measurements are especially important in jobs where you are paying the contractor by the square yard/inch rather than by the ton. Johnson says in the projects he has followed, contractors readily accept the reading from the MIT Scan T2 as accurate.

Light weight: Unlike many measuring devices, this tool is truly portable. It weighs about five pounds. If you’ve ever hauled around a Lightweight Falling Deflectometer on a job site, you know what we are talking about.

Quick: t only takes seconds to get a reading. Golish says you simply turn it on, press two buttons, walk across the surface and you’ve got a very accurate measure of thickness. You can also hover it above a fresh surface. During this year’s construction at MnROAD, says Dave Van Deusen, MnROAD operations engineer, they used it during a concrete paving project and a quick reading from the MIT Scan T2 showed the paving was getting too thick. The contractor was alerted, they adjusted the paver and got back on track.

Multitasking: MnDOT didn’t initially purchase these devices for measuring thickness. Golish says they originally got them for doweling projects. “They are great for locating dowel baskets and tie bars, to make sure the baskets haven’t moved,” he says. He has a document on the MnDOT website describing how they use it. This use of the scanner has been so successful, MnDOT already has a specification written for it for this use. Golish says they are almost done with the specification for using the MIT Scan T2 for its original purpose—measuring thickness.

The MIT Scan T2 has been around a few years, but Golish says there’s really nothing else like it out there in terms of measuring tools. The only drawback—and he’s writing this into the new spec—is that it doesn’t work that well with unbonded overlays. That’s because with an unbonded overlay, there may be steel underneath the original concrete that you don’t know about, and the scanner will pick that up. Likewise, you need to make sure you place the plate in the center of a 15 foot panel when doing a new concrete project or the very sensitive scanner will pick up the dowel basket if it’s too close.

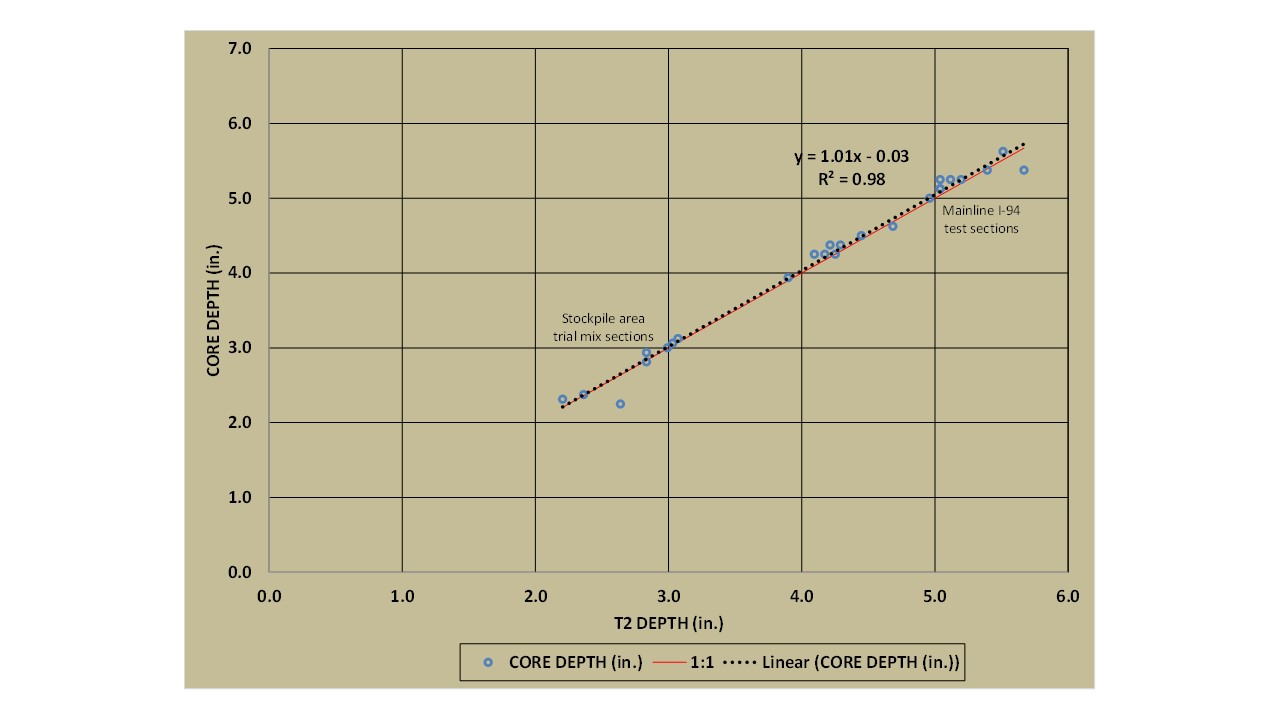

This graph shows correlation of MIT Scan T2 with cores based on our work during the NCAT study.

*The newest iteration of this tool is the MIT Scan T3

New Report on Intelligent Compaction

There's a new report out titled: Intelligent Compaction and Infrared Scanning Field Projects with Consulting Support. This was developed by agency member Missouri Department of Transportation and new associate member The Transtec Group.

Associate Profile: Collaborative Aggregates

Two hot trends in pavement design intersect where Collaborative Aggregates is currently situated: rejuvenators and environmental stewardship.

Collaborative Aggregates is a Sausalito-based LLC and closely affiliated with the Warner Babcock Institute for Green Chemistry. It has a plant-based, warm mix rejuvenator called Delta S, and it has been part of the research implemented by the NCAT/MnROAD partnership. In fact, says Pete Montenegro, construction marketing consultant for Collaborative Aggregates, their rejuvenator was qualified by that research partnership. That, he says, was a big breakthrough for his company.

Collaborative Aggregates was born out of research conducted by Warner Babcock and it is aligned with the 12 Principles of Green Chemistry. It’s vice president, Jay Bianchini, was one of the researchers who developed Delta S.

RAP

One trend that Delta S is trying to address is the increasing use of RAP in paving projects. Currently Collaborative Aggregates has some projects that used from 20% to 40% RAP that are 3 years old and performing well. These were all dense graded mix designs—between ¾ and 1 ½ inch thick lifts. Montenegro sees a growing demand for using more RAP in higher percentages, but that the equipment itself at the mixing plants will probably need to change to accommodate a higher percentage of RAP.

Field Results

Montenegro says the biggest hurdle for rejuvenators is durability; pavement professionals wonder what kind of life span they will get from the rejuvenated mix. That’s why the projects with Delta S out in the field—e.g. the NCAT/MnROAD partnership—are so important. “You can do all kinds of aging in the lab, but it’s just not the same as getting stuff out in the field,” says Montenegro.

Performance-based Specifications

One of the challenges, says Montenegro, is the chemistry of his organization’s plant-based rejuvenators. Many of the performance tests for paving materials are designed for petroleum-based products. So while he is an advocate for performance based specifications over recipe-based specs, he’s not sure the existing tests for Collaborative Aggregates’ product will provide accurate results. He says, the best that we can do now might be specs for the mix itself and not on the materials you use to get there.

In any case, Montenegro says the future is bright for binders and additives, and he anticipates a lot of changes in binder modifications and mixes.

May Research Pays Off Webinar

May 15: Development of Energy-, Cost-, and Environment-Based Life-Cycle Tool for In-Place Recycling Methods, Hasan Ozer, PhD and Imad Al-Qadi, Civil and Environmental Engineering Department, University of Illinois at Urbana-Champaign, Illinois Center for Transportation

Summary: The webinar will introduce the life-cycle assessment (LCA) tool developed for Federal Highway Administration (FHWA) to evaluate energy consumption and environmental impacts of in-place recycling techniques. The tool was developed consistent with the FHWA’s pavement LCA framework for the use of local and state highway agencies to make comparative assessment of in-place recycling techniques with their conventional alternatives. A comprehensive inventory database was developed through inventory modeling and data collection from contractors and agencies. The tool provides a user-friendly platform for state and local agencies to make life-cycle based decisions for selecting in-place recycling alternatives. Case studies will be presented to illustrate the potential use cases of the tool.

Connection information for Webinar

Playlist of previous 2017-18 Research Pays Off webinars